|

Item |

Standard specifications |

Option |

|

|

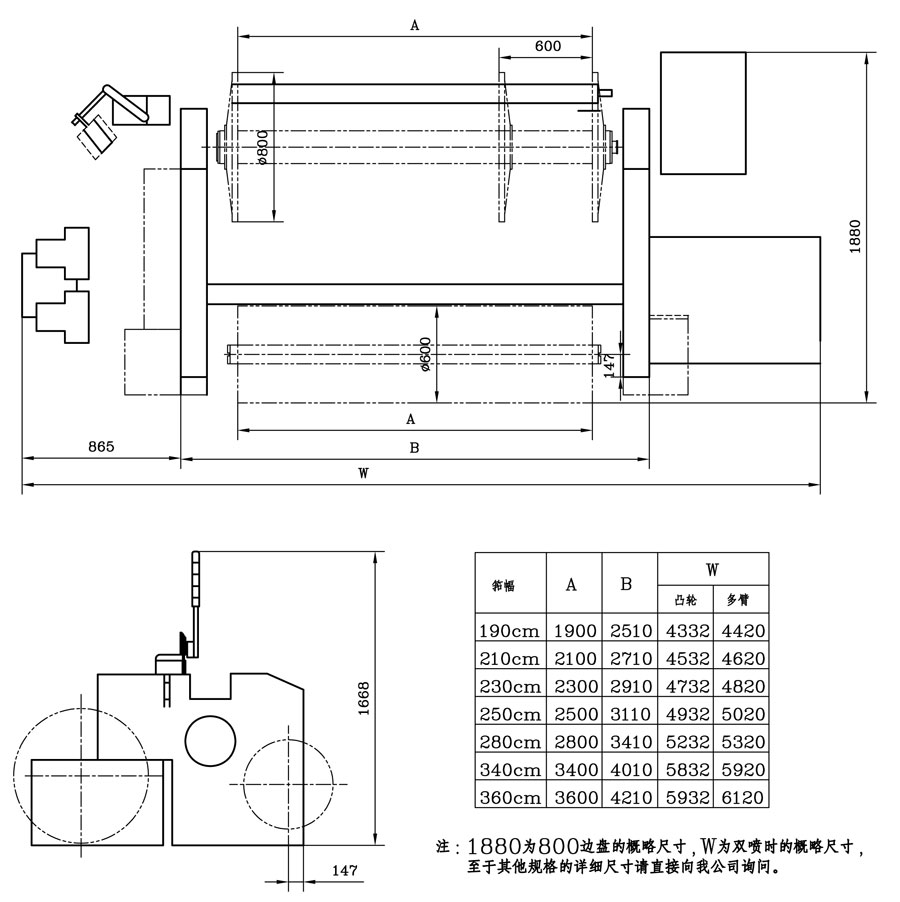

Reed space |

Nominal(cm) |

150, 170, 190, 210, 230, 250, 280,340,360 |

|

|

Useful reeding width (cm) |

0~-60cm (<250cm) |

0~80cm |

|

|

0~-80cm(>280cm) |

|

||

|

Weaving scope |

Staple |

Ne100-Ne2.55 |

|

|

Filament |

20d-1350d |

|

|

|

Weft selection |

|

Double spray, 4spray, 6spray |

8 spray |

|

Power |

|

Super start motor, motor drive directly |

Direct-drive motor |

|

The motor rating(KW) |

1.8、2.2、2.8、3.0、3.7、5.5KW(jacquard shedding) |

|

|

|

Weft insertion |

|

The main nozzle, nozzle with the type, use special reed |

Stretch nozzle |

|

|

Assist the main nozzle |

Flow screen display |

|

|

Weft insertion control |

Deputy nozzle relay control |

Air pressure screen display |

|

|

Sub-nozzle boosting system |

|

||

|

Opening |

|

Crank plain shedding: shaft number:4 |

Six linkage shedding |

|

|

Positive cam shedding: shaft number up to 8 |

Positive cam shedding: shaft number up to 10 |

|

|

|

Dobby shedding(electronic, floor-mounted)shaft number up to 16 |

|

|

|

|

Jacquard shedding |

Fabric label logo jacquard |

|

|

Let-off |

|

Electronic let off |

Left and right double beam, upper and lower double beam |

|

Variable disc diameter(mm) |

800,914,1000 |

|

|

|

Take-up |

|

Electronic take-up with automatic conversion of density |

|

|

The largest cloth diameter(mm) |

600mm(cam, dobby, jacquard shedding),520mm(crank shedding) |

Outside the machine Take-up |

|

|

Weft density range |

MTU: 6.6-80.5 picks/cm(16.7-204.4picks/inch) |

2.1-25.7picks/cm(5.4-65.4picks/inch) |

|

|

ETU:9.8-118.1 picks/cm(25-300picks/inch) |

5.9-118.1picks/cm(15-300picks/inch) |

||

|

Weaving length counting |

Displayed on the keyboard display,with the function of scale parking |

|

|

|

Beating-up |

|

Crank type sley feet more beating-up mechanism |

|

|

|

Section four linkage beating-up |

|

|

|

|

6-Section linkage beating-up (Reed width more than 250cm) |

Conjugate Cam Beating |

|

|

Length measuring weft |

|

Electric drum weft |

|

|

Wring side |

|

Planetary gear type |

|

|

Cut the weft |

|

Mechanical scissors |

Electronic scissors |

|

Temple |

|

Top side Temple |

Full Selvage Temple |

|

Stop device |

Weft stop |

Reflex ground weft detector |

|

|

Warp yarn |

Six columns dropper |

Warp Stop display, Left and right display functions |

|

|

Other |

Wring side parking broken ends,yarn end processing |

|

|

|

Fault display |

Operating screen |

|

|

|

4 color indicator light disply |

|

||

|

Lubrication |

|

Oil bath system for main driving parts,centralized lubrication(manual grease) |

Centralized lubrication(automaeic grease) |

|

Automation |

|

The computer control system |

|

|

|

Monitoring and self-diagnosis function |

|

|

|

|

|

automatic weft supply motion |

|